Sleevers

Adaptable Sleever Provides Performance without Fail

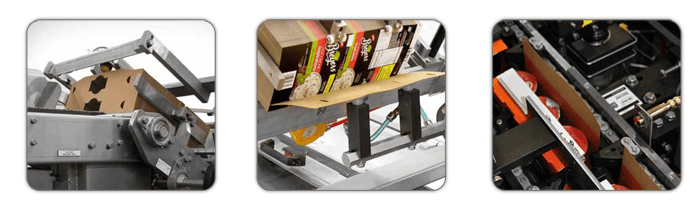

Apex™ sleever machines offer class-leading paperboard solutions for a wide range of products, sleeve styles and pack configurations. With speeds up to 300 sleeves per minute, easily adaptable product handling options, advanced servo technology and heavy gauge stainless steel construction, Apex delivers a non-stop powerhouse of performance, versatility and reliability.- Speeds up to 300 sleeves per minute

- Advanced servo technology

- Simple and repeatable changeovers

- Heavy-gauge stainless steel tubular frame for exceptional strength and durability

- Walk-in frame design for easy access and maintenance

- Fall through, balcony design overhead wiring and servo cable mounting ideal for dusty or wet environment

- Cantilevered design allows less reach to the carton flights for convenient operator access

- Simple solutions for wraparound, drop-through or neck-through sleeve applications

- Wide range of pack configurations

Apex™ sleevers offer rugged reliability combined with the latest innovative technologies to easily and precisely adapt to your application.

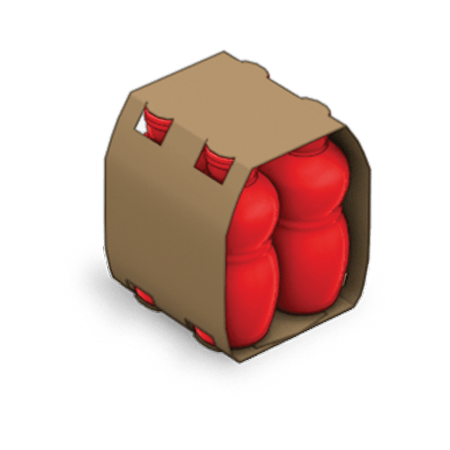

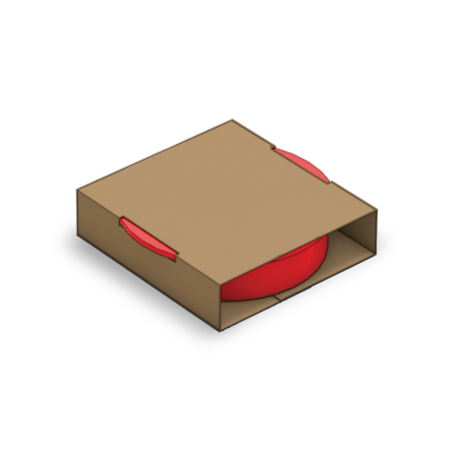

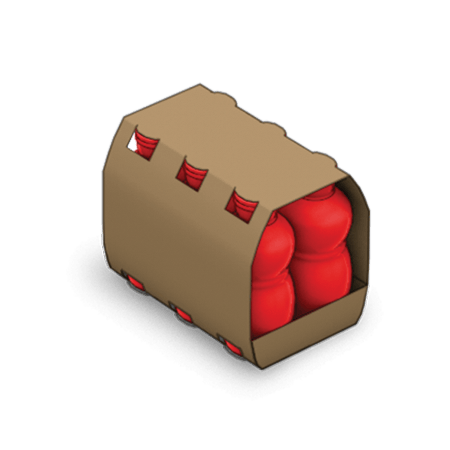

- Wraparound sleeves: Ideal for sleeving single products or multi-packs with top, side or bottom closure, available with bottom glue/top gusset or top glue/bottom gusset

- Drop-through sleeves: Perfect for single pack, multi-pack and multi-tier sleeving of tapered cups and containers

- Neck-through sleeves: Show off your product while providing excellent pack containment of necked bottles and containers, available with bottom glue/top gusset or top glue/bottom gusset

Douglas offers appropriately applied technologies for infeed conveying, collating and loading solutions that increase line efficiencies for soft, semi-rigid and rigid containers.

Simple balanced lane product infeeds use surge control to enhance line efficiency by increasing or decreasing machine speed to maintain pace with product delivery.

Timing screws are used for surgeable, semi-rigid containers requiring grouping, spacing or separation prior to

sleeve introduction.

Star wheels are used for soft products requiring surge control and spacing prior to sleeve introduction.

Unique live belt turning reliability for products requiring orientation prior to sleeving.

Fast, repeatable changeover feature offers multiple enhancements.

Changeover time – significantly reduces time to less than 5 minutes (time of changeover is dependent on extent of changeover)

Repeatability – rail positions are recipe-driven and locked in place to within +/- 1/32″

Flexibility – ability to place lanes where desired as opposed to centerline or fixed side adjustments and more customer options for generating product-specific recipes

Durability – infeed rail’s holding force can withstand high product pressure

Ergonomics – minimizing manual adjustments maximizes efficiency and promotes safety in the work environment

Automated changeovers offer dramatic improvements to line efficiencies and reduce operator errors.

- Sleever machine functions operate simultaneously instead of one at a time, dramatically increasing efficiencies

- Servo motors are readily programmed with excellent capability to adapt to changes and adjustments

- Fast, repeatable changeovers and simple adjustments when products or materials vary slightly

- Smooth, quiet operation reduces component wear for lower maintenance cost

- On-board diagnostics provide simple troubleshooting from the HMI

Precision sleeve blank and product control ensures consistent non-stop production for all product types.

- Magazines are intelligently designed to ensure precise blank placement and orientation.

- Sleeves are introduced from the top or bottom depending on sleeve design. Methods including sleeve flight lugs and capture rail systems maintain constant control of sleeve and product during the loading process.

- Closing and sealing are aided with a combination of static plows and live closures to minimize sleeve friction and resistance, ensuring consistently formed end products.

Specifications

| Drive: | Servo motors |

| Pitch: | Application dependent |

| Flight Chains: | Application dependent |

| Speed: | Variable up to 300 sleeves/minute or 800 products/minute (pitch, product and sleeve design dependent) |

| Product Size Range: | Per project specification |

| Package Size Range: | Per project specification |

| Magazine Capacity: | 6′ (1828.8 mm) standard, shorter or longer capacities optional |

| Frame: | Tubular steel |

| Adjustments: | Threaded screws, handwheels, scales and pointers Digital scales, phase adjustments and tool-less packages (application dependent) optional |

| Sleeve Setup/Feeder: | Rotary placer (application dependent) |

| Sleeve Positioning: | Traveling flights |

| Sleeve Closures: | Glue or locks |

| Glue System: | Nordson ProBlue® or per project specification |

| Compression: | Timing belt drive |

| Guarding: | Full length polycarbonate with extruded anodized aluminum frames |

| Electrical: | Allen Bradley programmable logic controller or per project specification Touch screen operator interface panel NEMA 12 wiring and enclosures NEMA 4 or 4X wiring and enclosures optional |

| Finish: | Gray metallic powder coat epoxy, other colors optional All parts in contact with product are stainless steel, anodized aluminum or food grade plastic OEM parts are per manufacturers’ standard finish |

| Power: | 230/480V, 50/60HZ, 3PH Single drop Other power sources available |

| Air: | 80-100 PSI (5.5-6.9 bar) Single drop |

Apex™ Sleevers easily accommodate large size ranges and pack patterns for the food and beverage industries.